Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=nurw20

Urban Water Journal

ISSN: (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/nurw20

Sediment transport prediction in sewer pipes

during flushing operation

Carlos Montes, Hachly Ortiz, Sergio Vanegas, Zoran Kapelan, Luigi Berardi &

Juan Saldarriaga

To cite this article:

Carlos Montes, Hachly Ortiz, Sergio Vanegas, Zoran Kapelan, Luigi Berardi

& Juan Saldarriaga (2022) Sediment transport prediction in sewer pipes during flushing operation,

Urban Water Journal, 19:1, 1-14, DOI: 10.1080/1573062X.2021.1948077

To link to this article: https://doi.org/10.1080/1573062X.2021.1948077

Published online: 16 Jul 2021.

Submit your article to this journal

Article views: 218

View related articles

View Crossmark data

RESEARCH ARTICLE

Sediment transport prediction in sewer pipes during flushing operation

Carlos Montes

a

, Hachly Ortiz

a

, Sergio Vanegas

a

, Zoran Kapelan

b

, Luigi Berardi

c

and Juan Saldarriaga

a

a

Department of Civil and Environmental Engineering, Universidad de los Andes, Bogotá, Colombia;

b

Department of Water Management, Delft

University of Technology, Delft, Netherlands;

c

Department of Engineering and Geology, Università Degli Studi “G. d’Annunzio” Chieti, Pescara, Italy

ABSTRACT

This paper presents a novel model for predicting the sediment transport rate during flushing operation in

sewers. The model was developed using the Evolutionary Polynomial Regression Multi-Objective Genetic

Algorithm (EPR-MOGA) methodology applied to new experimental data collected. Using the new model,

a series of design charts were developed to predict the sediment transport rate and the required flushing

operation time for several pipe diameters. Accurate results (i.e. sediment transport rates) were obtained

when applied to a case study in a combined sewer pipe in Marseille, as reported in the literature. The

novelty of the model is the inclusion of the pipe slope, the inflow ‘dam break’ hydrograph, and the

sediment properties as explanatory parameters. The new model can be used to predict flushing efficiency

and design new flushing cleaning schedules in sewer systems.

ARTICLE HISTORY

Received 19 February 2021

Accepted 21 June 2021

KEYWORDS

Flushing efficiency; sediment

transport; sewer cleansing;

sewer flushing

1. Introduction

Sediment deposition and accumulation are well-known issues

in sewer systems modelling. The presence of permanent depos-

its of material at the bottom of sewer pipes produces several

problems, such as reduced flow capacity and premature com-

bined sewer overflows (Ashley et al.

2004

; Rodríguez et al.

2012

). Flushing waves, also known as surge flushing technique,

have been identified as an efficient (Bong, Lau, and Ab Ghani

2016

; Yang et al.

2019

) and cost-effective (Campisano et al.

2019

; Campisano, Creaco, and Modica

2007

) method for solving

these problems. It aims to remove the deposited sediments by

generating waves, which are produced by the upstream sto-

rage and further discharge of water volumes. These flushing

waves increase the bottom shear stress and induce the scour

and resuspension of the deposited material.

The above flushing technique has been applied in several case

studies following operational and management practice guides

(Fan

2004

; Saegrov

2006

; NEIWPCC

2003

) in countries such as

Germany, France, the USA and the UK. As an example, Saegrov

(

2006

) suggest flushing waves to remove settled deposits in sew-

ers ranging from 100 mm to 1200 mm pipe diameter with

a mandatory cleaning frequency once in 1 to 5 years. However,

these guides do not specify important flushing parameters such as

the hydraulic and pipe characteristics (i.e. length, slope and

hydraulic roughness, among others), sediment properties and

flushing volume. The lack of information on these specifications

has contributed to the fact that existing flushing practices tend to

be oversized. As an instance, Dettmar (

2007

) compared design

tables developed by using extensive field studies and mathema-

tical simulations (Chebbo et al.

1996

; Dettmar

2005

; Lainé et al.

1998

) and concluded that smaller flushing volumes and water

storage heights achieve the same flushing length and efficiency

in removing the volume of deposited sediments, compared to

operational and management practice guides.

In the last decades, several studies have quantified the flush-

ing efficiency in terms of (a) reduction of volume and/or weight

of sediments (Bong, Lau, and Ab Ghani

2016

; Campisano et al.

2019

; Campisano, Creaco, and Modica

2008

,

2004

; Creaco and

Bertrand-Krajewski

2009

; Guo et al.

2004

; Ristenpart

1998

;

Shahsavari, Arnaud-Fassetta, and Campisano

2017

), (b) changes

in deposited bed thickness (Bong, Lau, and Ab Ghani

2013

,

2016

;

Campisano et al.

2019

; Campisano, Creaco, and Modica

2008

,

2007

,

2004

; Dettmar, Rietsch, and Lorenz

2002

; Ristenpart

1998

;

Shahsavari, Arnaud-Fassetta, and Campisano

2017

; Shirazi et al.

2014

), (c) variation of concentrations of total suspended solids

(Ristenpart

1998

; Sakakibara

1996

), (d) increase in the bottom

shear stress (Bertrand-Krajewski et al.

2003

; Campisano, Creaco,

and Modica

2008

; Campisano and Modica

2003

; Dettmar,

Rietsch, and Lorenz

2002

; Ristenpart

1998

; Schaffner and

Steinhardt

2006

; Yang et al.

2019

), (e) length of the channel

that can be potentially cleaned (Bertrand-Krajewski et al.

2003

;

Bong, Lau, and Ab Ghani

2013

; Dettmar, Rietsch, and Lorenz

2002

; Shahsavari, Arnaud-Fassetta, and Campisano

2017

; Yang

et al.

2019

) and (f) stored water volume discharged (Bertrand-

Krajewski et al.

2003

; Dettmar, Rietsch, and Lorenz

2002

; Fan et al.

2001

). These studies were carried out in both laboratory and real

sewer flumes using different sediment characteristics, stored

water volumes and geometrical characteristics of the flume. As

a result, a list of parameters affecting the flushing efficiency was

identified and classified in three main groups: (i) flushing hydrau-

lics, (ii) pipe geometry and (iii) sediment properties. Flushing

hydraulic parameters include water velocity (V

f

), shear stress (τ),

the water level in the pipe (Y), flowrate (Q), stored water head

(h

o

) and stored water volume discharged (V

a

). In the pipe

CONTACT

Carlos Montes

cd.montes1256@uniandes.edu.co

URBAN WATER JOURNAL

2022, VOL. 19, NO. 1, 1–14

https://doi.org/10.1080/1573062X.2021.1948077

© 2021 Informa UK Limited, trading as Taylor & Francis Group

geometry, parameters as the slope (S

o

), diameter (D), length (L),

cross-section shape factor (β) and composite roughness (k

c

) have

been included. Finally, sediment properties include mean parti-

cle diameter (d), sediment thickness (y

s

) and width (W

b

), specific

gravity (SG), porosity (η) and density (ρ

s

).

The previous three groups of parameters have been used for

implementing numerical models useful to quantify the flushing

efficiency. Models found in the literature are focused on (i)

solving complex mathematical structures, (ii) proposing simple

dimensionless equations for estimating sediment transport

rates and (iii) using Machine Learning (ML) and Artificial

Intelligence (AI) techniques for finding patterns in data and

predicting bedload and suspended load transport.

In the first approach, the one-dimensional Saint-Venant equa-

tions (Campisano, Creaco, and Modica

2006

; Campisano and

Modica

2003

; De Sutter, Huygens, and Verhoeven

1999

), coupled

with the Exner equation for uniform (Campisano, Creaco, and

Modica

2007

,

2004

; Creaco and Bertrand-Krajewski

2009

; Shirazi

et al.

2014

) and non-uniform (Campisano et al.

2019

) sediments,

are used for predicting bed sediment thickness changes during

the flushing operation. More complex models involve the two-

dimensional (Caviedes-Voullième et al.

2017

; Yu and Duan

2014

)

and three-dimensional (Schaffner and Steinhardt

2006

) solutions

of the Saint-Venant equations. An example of the literature

models is as follows:

@

U

@

t

þ

@

F U

ð Þ

@

x

¼

D U

ð Þ

(1)

where U, F U

ð Þ

and D U

ð Þ

are defined as follows:

U ¼

A

Q

A

s

2

4

3

5; F U

ð Þ ¼

Q

V

f

Q þ

F

h

ρ

1

1 ρ

Q

s

2

4

3

5; D U

ð Þ ¼

0

gA S

o

V

f

2

k

c

2

R

4=3

�

�

0

2

4

3

5

(2)

where F

h

is the hydrostatic force over the cross-section, ρ the

water density, R the hydraulic radius, A is the cross-section

wetted area, A

s

is the cross-section sediment bed area and Q

s

the sediment flow rate.

In the second approach mentioned above, several authors

have developed analytical equations for predicting the number

of flushes required to move the deposited sediment bed (Bong,

Lau, and Ab Ghani

2013

; Chebbo et al.

1996

). Likewise, the effects

of pipe slope, bottom roughness, storage water level, and down-

stream water level, among others (Yang et al.

2019

; Kuriqui,

Koçileri, and Ardiçlioğlu

2020

) have also been studied in the

past. As an example, Bong, Lau, and Ab Ghani (

2013

) proposed

the following equation, where n

f

is the number of flushes required

to move the deposited sediment bed by 1 m:

n

f

¼

251:43y

s

þ

6:57

(3)

In the third approach, several studies using ML and AI have

been developed for predicting both bedload and suspended

load transport in sewers, flumes, and streams. Several techni-

ques as Artificial Neural Networks (Wan Mohtar et al.

2018

;

Bajirao et al.

2021

), Random Forests (Khosravi et al.

2020

;

Safari

2020

; Montes, Kapelan, and Saldarriaga

2021

), and

Vector Machines (Ebtehaj et al.

2017

), among others, have

been trained with experimental data collected at laboratory

scale and tested with benchmark data found in the literature.

These models outperform traditional regression formulas dur-

ing the training stage but tend to underperform when applied

to external datasets collected in sewers and flumes (Montes,

Kapelan, and Saldarriaga

2021

), i.e., during the testing stage.

Numerical studies mentioned above, based on the solution

of the Saint-Venant and Exner coupled-equations for sediment

transport under unsteady flow conditions, show similar predic-

tions of the sediment thickness changes compared to the

experimental data collected, i.e., the models show good accu-

racy prediction. Despite the solutions and simulations based on

Saint Venant-Exner equations showing good accuracy, in prac-

tice, the application for operational and management practices

is complex and non-pragmatic. Also, the analytical and dimen-

sionless equations proposed by Bong, Lau, and Ab Ghani (

2013

)

and Yang et al. (

2019

), do not include important parameters

such as the pipe/flume geometry and the sediment character-

istics. Finally, AI and ML models are largely black-box models

(Montes, Kapelan, and Saldarriaga

2021

), limiting their inter-

pretability for practical applications.

The above gaps are addressed here by developing a new

parsimonious regression-based model using the Evolutionary

Polynomial Regression – Multi-Objective Genetic Algorithm (EPR-

MOGA) (Giustolisi and Savic

2009

) strategy. EPR-MOGA is a data-

driven method which combines genetic algorithm with

evolutionary computing for finding polynomial structures. Due

to its characteristics, the returned symbolic expressions can be

compared with existing models in terms of the input variables,

exponent coefficients, and technical insight on the phenomenon

(Montes et al.

2020a

) while reducing the risk of overfitting.

This paper aims to propose a new model for predicting the

sediment transport rate during flushing operations in sewers.

The novelty of this model is the inclusion of flushing ‘dam break’

hydrograph, pipe geometry, and deposited sediment character-

istics in a simple polynomial expression. The new model devel-

oped here can be used to optimize flushing schemes and reduce

the volume of water required for cleaning sewers.

2. Experimental methods and data collection

The collection of experimental data was carried out in two

pipes with diameters of 209 mm and 595 mm (Montes et al.

2020b

), both located at the Hydraulics Laboratory of the

University of the Andes, Colombia. A sediment bed with a near-

uniform thickness and width was prepared at the bottom of the

pipes, using uniformly graded sediment material ranging from

0.21 mm to 2.6 mm. These particles had a specific gravity

between 2.57 and 2.67, which was calculated using the pycn-

ometer method (ASTM D854-14

2014

). The experiments were

carried out under unsteady flow conditions, simulating the

‘dam break’ waves produced during a flushing event. The

methodology used for data collection and further details of

both experimental setups are described below.

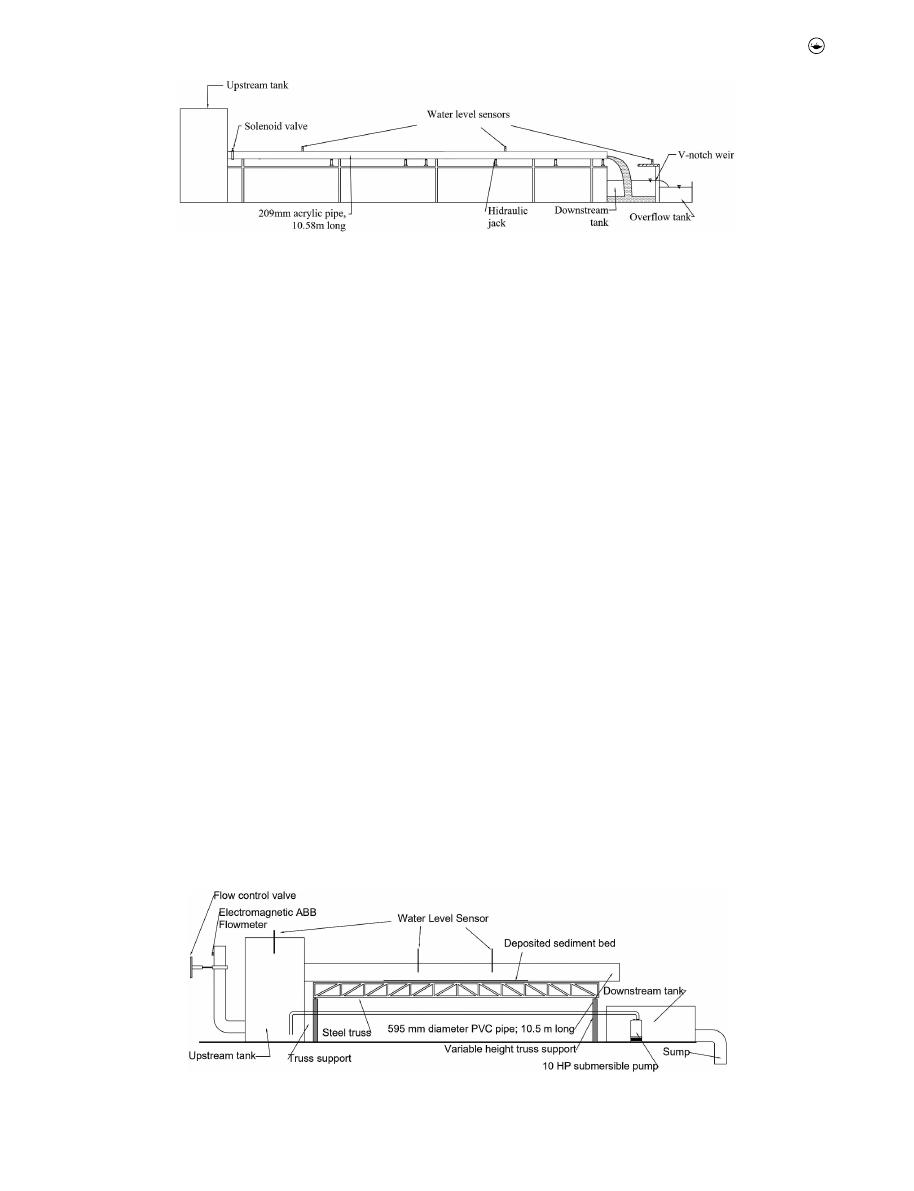

2.1. 209 mm pipe setup

The 209 mm diameter acrylic pipe had a length of 10.58 m and

was supported on six hydraulic jacks, which allowed to vary the

pipe slope between 0.64% and 1.20%. This pipe was connected

2

C. MONTES ET AL.

to a 200 mm solenoid valve, which controlled the inflow into

the setup from a 3.5 m

3

upstream tank. A downstream tank

with a V-Notch weir was used to measure the water discharge.

A real-time water level sensor was used to measure the water

height over the weir to calculate the water discharge rate using

the V-Notch equation. The calculated discharge was also

checked using an ABB- Electromagnetic flowmeter sensor

installed upstream of the pipe. Two additional real-time water

level sensors were installed along the pipe, aiming to measure

the stage hydrograph produced by the flushing waves.

Figure 1

shows the general scheme of the experimental setup.

The experimental data was collected as follows. Firstly, the

solenoid valve was fully opened, allowing a base flowrate ran-

ging from 0.002 l s

−1

to 0.414 l s

−1

. The opening of this valve

simulates the ‘dam break hydrograph’ produced during

a flushing operation in a real sewer pipe (e.g. using a Hydrass

or a Hydroself flushing gate). Secondly, a sediment bed with

near-uniform thickness and width was located at the bottom of

the pipe. At this point, the base flowrate helped the formation

of the deposited bed along a 3.3 m section. Thirdly, the sole-

noid valve was completely closed for storing a volume of water

between 0.10 m

3

and 0.31 m

3

in the upstream tank. Fourthly,

the solenoid valve was opened between 60% and 100% and

the opening time was set to 15 sec for all tests. When the first

discharged wave reached the sediment bed, the movement of

the bed was tracked over time. The sediment velocity (V

s

) was

calculated using the values of the time and deposited bed

displacement during the peak flow. The above procedure was

repeated for different accumulated upstream water volume

and percentage of the solenoid valve opening.

2.2. 595 mm pipe setup

The pipe was 10.5 m long and supported on a mechanical steel

truss, which allowed to modify the slope in a range between

0.04% and 3.44%. The base flow for the experiments, ranging

from 1.03 l s

−1

to 9.98 l s

−1

, was provided by a 40 BHP pump

that supplied water to a 30 m

3

upstream storage which was

directly connected to the pipe. For evaluating unsteady flow

conditions in this pipe, a second 10 BHP submersible pump was

located inside the downstream tank. This pump was directly

connected to the upstream tank and was controlled with

a variable frequency drive programmed before the experiment

to create a pulse with a maximum peak flow of 30 l s

−1

. Three

water level sensors were used to record water depths in the

experimental setup. Two of them were installed in the pipe to

collect the stage hydrograph, and one was installed in the

upstream tank. Full details of the experimental setup were

described in Montes et al. (

2020b

) and are shown in

Figure 2

.

For this setup, the data was collected as follows. Firstly, the

pipe slope was adjusted using the mechanical steel truss and

measured with a dumpy level. Secondly, the flow control valve

on the upstream tank was opened to supply a base flow to the

pipe. Thirdly, a deposited sediment bed with a near-uniform

width was prepared at the bottom of the pipe over a minimum

length of 1.5 m. At this point, to compare the flushing efficiency

under similar conditions, the maximum sediment bed velocity

was verified as 0.03 m s

−1

. If this condition was not fulfilled, the

pipe slope or the base flow were changed. Fourthly, the sub-

mersible pump, with its variable frequency drive, was activated

to simulate the ‘dam break hydrograph’, which is similar to those

produced by the flushing gates in real sewers. The water levels

were recorded each 0.025 s and the position of the sediment bed

Figure 1.

Experimental setup used to collect the unsteady flow data in the 209 mm acrylic pipe.

Figure 2.

Experimental setup used to collect the unsteady flow data in the 595 mm PVC pipe.

URBAN WATER JOURNAL

3

was tracked. The sediment velocity was calculated using the

same procedure followed on the acrylic setup.

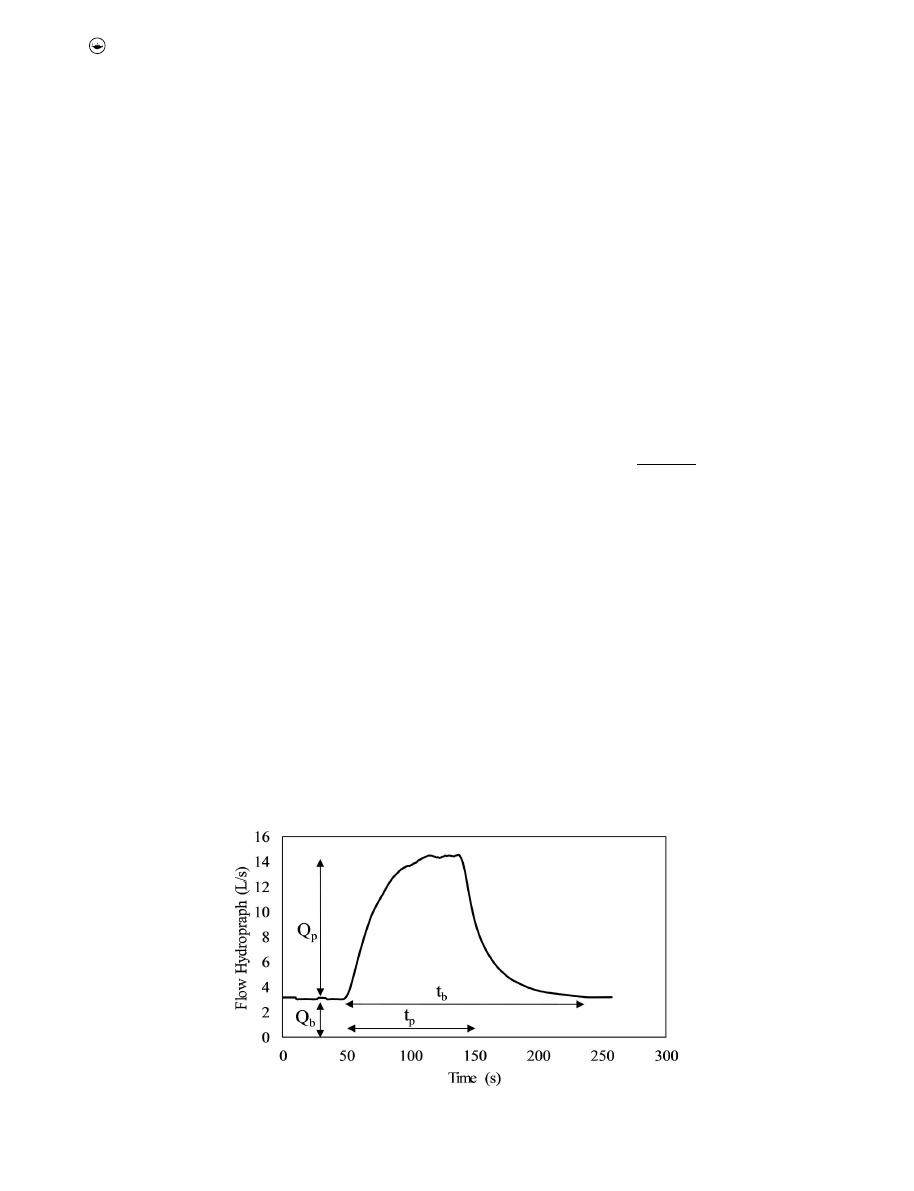

2.3. Experimental data collected

Using the experimental rig and approach described above,

a total of 57 and 64 experiments were carried out in the

209 mm acrylic pipe and 595 mm PVC pipe, respectively.

Several variables related to the pipe geometry, sediment prop-

erties, and flushing hydraulics, including the base time (t

b

),

peak time (t

p

), base flow (Q

b

), and peak flow (Q

p

) were recorded

in each experiment, as shown in

Figure 3

. The experimental

data collected in both acrylic and PVC pipes are presented in

Table 1

, where S

o

is the pipe slope, D the pipe diameter, Y the

water level in the pipe, R the hydraulic radius, d the mean

particle diameter, SG the specific gravity, y

s

the sediment thick-

ness, V

f

the water velocity, and V

s

the sediment velocity.

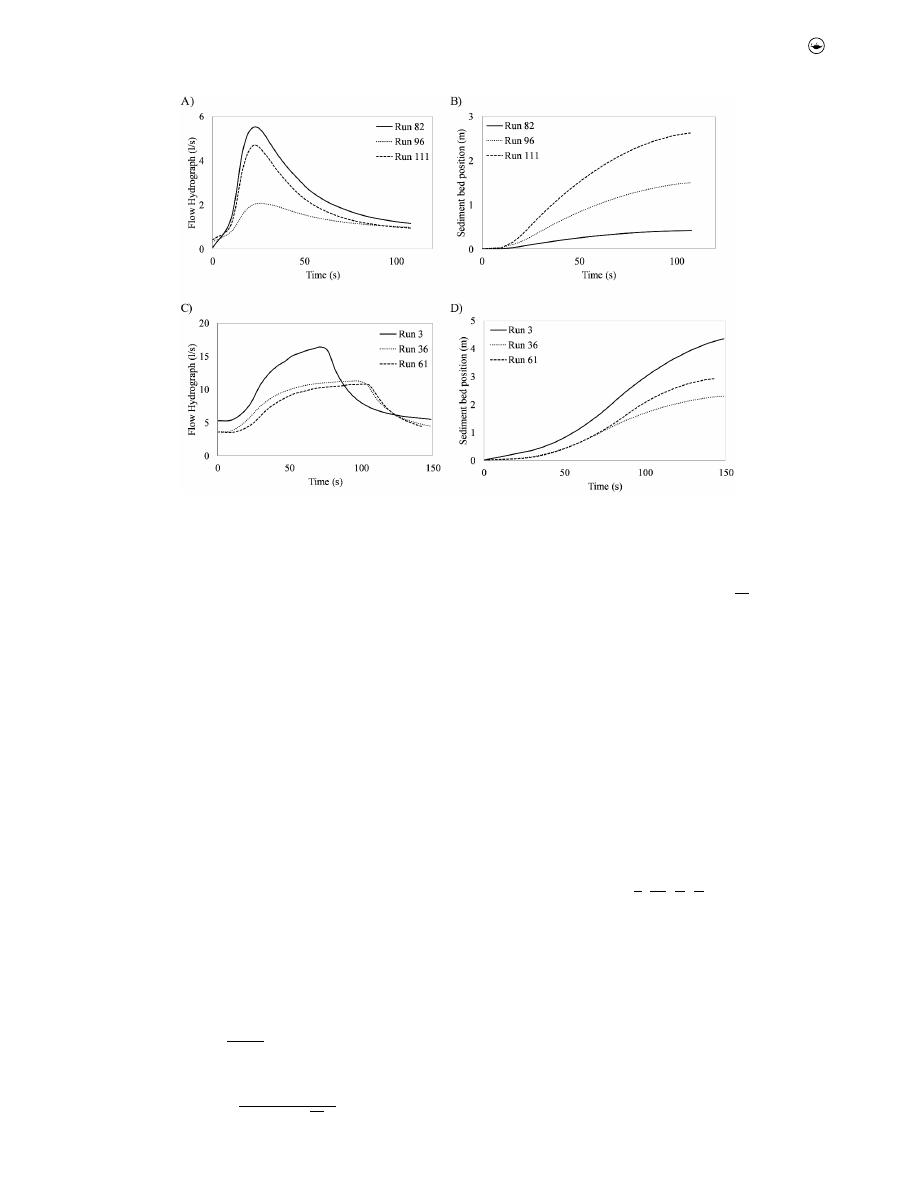

A flushing discharge hydrograph and a plot showing the

sediment bed position related with each run are presented in

Table 1

. The shape and magnitude of the hydrograph are

directly related to the sediment bed velocity, and consequently,

the sediment bed position. As an example, for six runs, the

variation in the sediment bed position and hydrograph char-

acteristics, in both acrylic and PVC pipe, are presented in

Figure 4

. Full details of each run shown in

Figure 4

are pre-

sented in

Table 1

.

Figure 4(a, b

) show the relation between the flushing dis-

charge hydrograph and the sediment bed position for tests

conducted on the acrylic pipe. As seen in these figures, particle

size is a more important variable in defining the sediment

position, compared to the peak flow in the hydrograph. Even

though the run 82 considers a higher peak flow (Q

p

= 5.55 l s

−1

),

the final position of the sediment bed (= 0.41 m) is lower than

the run 96 (= 2.62 m) when the peak flow is lower (Q

p

= 2.08 l

s

−1

). This occurs because the particle diameter is more relevant

compared to the peak flow.

Figure 4(c, d

) show the relation between the flushing dis-

charge hydrograph and the sediment bed position for tests in

595 mm setup. The relationship between the discharge hydro-

graph and the sediment bed position is proportional. For run

no. 36 and 61, the mean particle diameter was 2.60 mm, but the

pipe slope was 1.65% and 1.82%, respectively.

Figure 4(d

)

shows that maintaining the mean particle diameter constant

as the pipe slope increases, the final bed position increases.

3. Model development

3.1. Graphical analysis

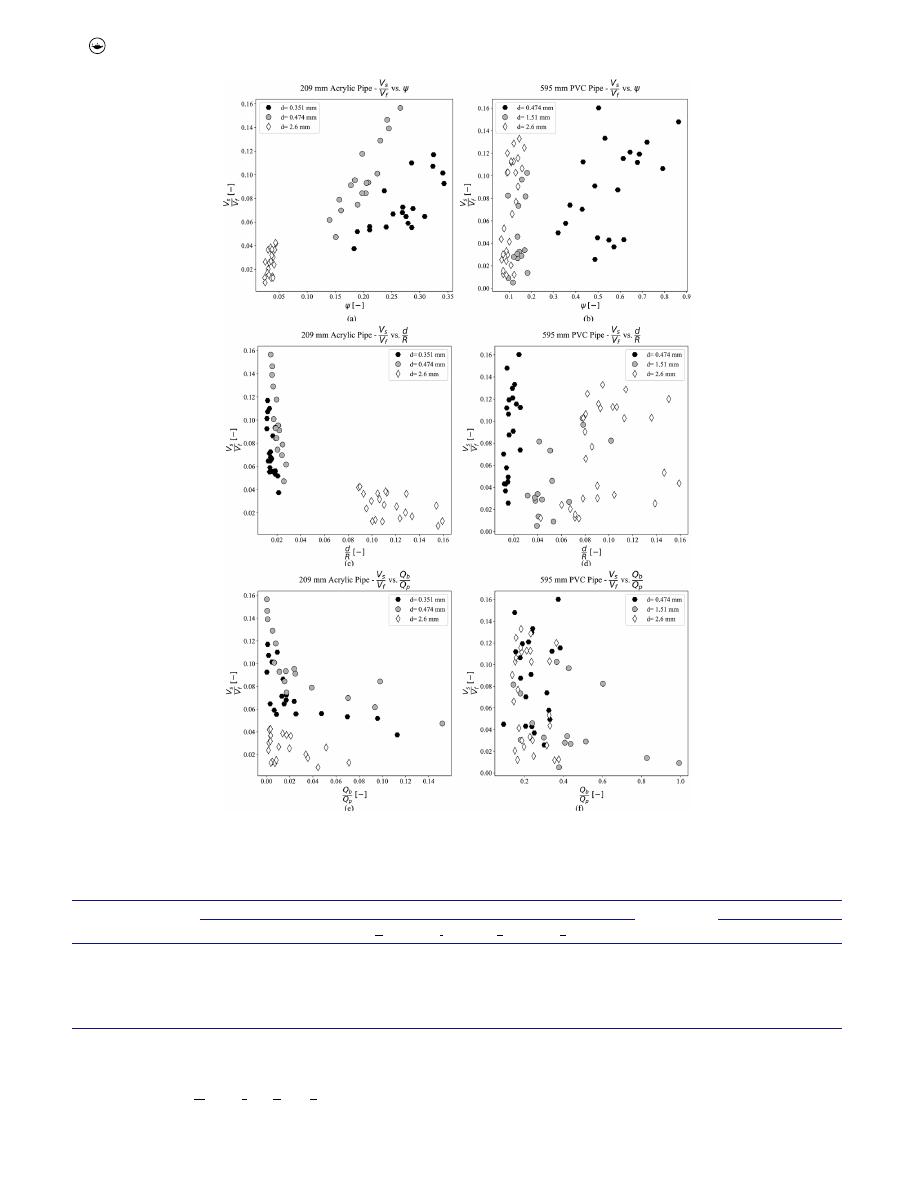

A graphical analysis was developed to visualize the relationships

between the variables collected in each experiment. The rela-

tionship between sediment velocity and flow velocity (V

s

=

V

f

) was

plotted against other dimensionless parameters, as shown in

Figure 5

. These dimensionless parameters have been previously

identified as relevant for predicting sediment transport in sewer

pipes in previous literature (Ab Ghani and Azamathulla

2011

;

Ebtehaj and Bonakdari

2016

; May et al.

1996

; Kuriqui, Koçileri,

and Ardiçlioğlu

2020

; Montes, Kapelan, and Saldarriaga

2021

).

Two of these parameters include the dimensionless grain size

(d=R) and the Shields parameter (ψ), defined in Equation (4):

ψ ¼

RS

o

SG

1

ð

Þ

d

(4)

Based on the results shown in

Figure 5

, the following observa-

tions can be made:

●

In general, higher values of the Shields parameter lead to

higher values of V

s

=

V

f

. This can be clearly seen in the acrylic

pipe (

Figure 5(a

)) because of the constant slope value

adopted in the experimental rig. Furthermore, high values

of S

o

and R lead to higher sediment velocities due to higher

critical shearing stress (i.e. the applied forces are higher

than the submerged weight of the particle). In contrast,

deposited materials with high density of particle diameters

result in lower sediment velocities.

●

The direct relationship between V

s

=

V

f

and the Shields

parameter coincides with the inversely proportional rela-

tionship between V

s

=

V

f

and d=R, shown in

Figure 5(c,d)

.

This is observed because the Shields parameter includes

the ratio R=d, as shown in Equation (4).

Figure 3.

Variable definition of the flushing discharge hydrograph.

4

C. MONTES ET AL.

Table 1.

Experimental data collected for studying flushing waves efficiency on sewer pipes.

Run no.

S

o

D

Y

R

d

SG

y

s

t

b

t

p

Q

b

Q

p

V

f

V

s

(%)

(mm)

(mm)

(mm)

(mm)

(-)

(mm)

(s)

(s)

(l s

−1

)

(l s

−1

)

(m s

−1

)

(m s

−1

)

1

0.805

595

70.35

41.96

0.47

2.66

10.14

154

59

5.27

25.48

1.02

0.07

2

0.805

595

57.43

34.62

0.47

2.66

8.26

141

57

5.45

16.76

0.89

0.05

3

0.805

595

53.61

31.34

0.47

2.66

10.53

131

57

5.45

16.49

0.82

0.04

4

1.186

595

57.82

36.46

0.47

2.66

2.49

121

59

4.89

20.53

1.20

0.05

5

1.229

595

54.70

31.17

0.47

2.66

12.55

115

55

4.81

15.97

0.99

0.03

6

1.229

595

61.66

36.67

0.47

2.66

9.91

120

55

5.07

20.27

1.14

0.04

7

1.229

595

50.94

31.92

0.47

2.66

3.90

183

58

1.03

11.10

1.09

0.05

8

1.229

595

67.63

39.54

0.47

2.66

12.15

124

57

5.03

24.47

1.19

0.05

9

1.229

595

62.04

37.24

1.51

2.66

8.97

39

33

9.98

12.06

1.16

0.02

10

1.525

595

42.69

22.71

1.51

2.66

13.54

117

58

5.17

11.84

0.87

0.02

11

2.034

595

37.55

19.29

1.51

2.66

13.28

111

59

4.92

11.54

0.89

0.09

12

2.331

595

35.95

19.45

1.51

2.66

10.96

182

57

3.99

10.93

0.97

0.10

13

0.763

595

67.43

38.31

1.51

2.66

14.87

113

56

4.42

11.71

0.90

0.00

14

0.763

595

70.23

39.60

1.51

2.66

15.99

126

69

9.13

22.46

0.92

0.03

15

0.763

595

81.75

47.82

1.51

2.66

13.12

135

63

9.40

31.43

1.07

0.04

16

1.123

595

58.13

34.59

1.51

2.66

9.55

118

60

9.23

17.93

1.04

0.03

17

1.123

595

64.66

37.76

1.51

2.66

11.97

118

57

9.37

22.36

1.10

0.04

18

1.186

595

57.59

29.85

1.51

2.66

19.13

149

79

3.59

20.04

0.92

0.07

19

1.186

595

52.88

28.98

1.51

2.66

14.70

149

88

3.95

16.45

0.91

0.04

20

1.186

595

64.30

36.57

1.51

2.66

14.31

195

93

3.51

24.52

1.09

0.09

21

0.847

595

69.70

40.25

1.51

2.66

13.64

185

55

3.72

20.71

0.99

0.03

22

0.847

595

51.24

28.32

1.51

2.66

13.83

104

8

7.28

7.33

0.76

0.01

23

1.589

595

32.25

14.83

1.51

2.66

14.35

118

82

4.36

7.24

0.65

0.05

24

0.847

595

63.16

36.41

2.60

2.64

12.98

120

76

4.71

12.53

0.92

0.01

25

0.847

595

66.11

36.30

2.60

2.64

17.48

156

86

4.10

16.57

0.90

0.01

26

0.847

595

72.84

43.20

2.60

2.64

10.93

161

83

4.13

20.88

1.06

0.03

27

0.847

595

105.64

61.10

2.60

2.64

15.39

167

65

4.11

24.98

1.34

0.02

28

1.059

595

62.36

34.80

2.60

2.64

15.48

143

75

4.22

11.91

0.99

0.01

29

1.059

595

54.15

28.78

2.60

2.64

16.77

154

83

4.02

16.63

0.85

0.03

30

1.186

595

59.13

33.26

2.60

2.64

14.30

143

67

3.69

19.77

1.01

0.03

31

1.186

595

67.08

38.56

2.60

2.64

13.76

148

74

3.57

23.71

1.14

0.02

32

1.483

595

39.34

18.73

2.60

2.64

16.36

176

88

3.45

10.96

0.73

0.02

33

1.483

595

46.74

24.88

2.60

2.64

14.66

136

80

3.52

15.45

0.91

0.03

34

1.483

595

53.25

28.81

2.60

2.64

15.54

186

72

3.39

19.73

1.01

0.04

35

1.483

595

59.57

32.28

2.60

2.64

16.95

184

79

3.42

23.61

1.10

0.07

36

1.653

595

38.51

16.34

2.60

2.64

19.13

134

82

3.75

11.36

0.69

0.03

37

1.653

595

46.08

23.02

2.60

2.64

17.21

141

84

3.76

15.96

0.90

0.09

38

1.653

595

52.56

28.02

2.60

2.64

16.18

146

70

3.71

20.08

1.04

0.12

39

1.653

595

59.13

33.13

2.60

2.64

14.58

147

64

3.64

23.79

1.19

0.12

40

1.568

595

38.73

18.76

0.47

2.66

15.60

135

87

3.64

11.58

0.76

0.06

41

1.568

595

46.16

24.41

0.47

2.66

14.80

142

81

3.73

15.96

0.92

0.08

42

1.568

595

53.90

29.62

0.47

2.66

14.77

146

87

3.66

20.35

1.07

0.09

43

1.568

595

59.10

34.08

0.47

2.66

12.39

151

81

3.75

24.25

1.20

0.13

44

1.822

595

37.55

18.70

0.47

2.66

14.29

140

87

4.06

11.92

0.82

0.09

45

1.822

595

45.29

22.96

0.47

2.66

16.33

148

88

4.00

16.48

0.95

0.13

46

1.822

595

51.59

29.70

0.47

2.66

11.33

152

81

3.95

20.87

1.17

0.14

47

2.034

595

35.08

19.49

0.47

2.66

9.71

121

84

3.97

10.64

0.92

0.15

48

2.034

595

42.85

24.99

0.47

2.66

9.05

161

89

3.26

14.75

1.11

0.13

49

2.034

595

50.35

30.68

0.47

2.66

6.79

7

78

3.56

20.07

1.32

0.14

50

2.034

595

54.22

33.47

0.47

2.66

5.64

178

60

3.56

23.79

1.42

0.21

51

2.246

595

34.90

21.54

0.47

2.66

4.68

127

75

4.36

11.38

1.09

0.13

52

2.246

595

42.64

25.31

0.47

2.66

7.95

159

77

3.78

15.90

1.19

0.15

53

2.246

595

35.17

17.28

2.60

2.64

13.82

131

78

4.07

11.19

0.86

0.10

54

2.246

595

42.78

22.75

2.60

2.64

13.58

142

88

3.62

15.55

1.06

0.14

55

2.246

595

47.24

27.46

2.60

2.64

9.96

146

85

3.62

19.82

1.24

0.17

56

2.246

595

52.77

31.74

2.60

2.64

8.10

142

79

3.72

23.74

1.40

0.18

57

2.076

595

36.93

19.14

2.60

2.64

12.77

136

85

3.90

11.87

0.90

0.09

58

2.076

595

43.16

24.38

2.60

2.64

10.84

11

77

3.69

16.02

1.09

0.12

59

2.076

595

50.20

28.50

2.60

2.64

11.99

153

92

3.67

20.34

1.21

0.14

60

2.076

595

54.70

32.31

2.60

2.64

9.85

154

79

3.79

24.16

1.35

0.14

61

1.822

595

36.34

17.74

2.60

2.64

14.46

123

84

3.54

10.84

0.79

0.04

62

1.822

595

43.56

25.20

2.60

2.64

9.63

162

85

3.20

15.12

1.05

0.12

63

1.822

595

50.97

30.34

2.60

2.64

8.79

171

78

3.18

19.05

1.21

0.09

64

1.822

595

56.21

32.54

2.60

2.64

11.66

168

87

3.25

23.71

1.25

0.11

65

0.644

209

34.99

20.17

2.60

2.64

5.60

101

18

0.08

3.80

0.55

0.02

66

0.644

209

49.27

27.29

2.60

2.64

8.22

101

16

0.01

6.60

0.68

0.02

67

0.644

209

51.63

27.99

2.60

2.64

9.89

101

14

0.02

6.84

0.68

0.02

68

0.644

209

28.15

16.32

2.60

2.64

4.98

101

20

0.14

1.99

0.48

0.01

69

0.644

209

30.78

16.70

2.60

2.64

7.96

101

19

0.11

2.45

0.47

0.00

70

0.644

209

40.49

23.10

2.60

2.64

6.26

101

17

0.08

4.73

0.61

0.02

71

0.644

209

53.26

29.33

2.60

2.64

8.49

101

15

0.02

7.37

0.71

0.03

72

0.644

209

35.58

20.28

2.60

2.64

6.26

101

20

0.12

3.62

0.55

0.01

73

0.644

209

40.61

23.32

2.60

2.64

5.82

101

18

0.06

4.58

0.62

0.02

(Continued)

URBAN WATER JOURNAL

5

●

Figure 5(e

) shows the inversely proportional relationship

between V

s

=

V

f

and the dimensionless parameter Q

b

=

Q

p

,

meaning that higher and steeper discharge hydrographs

(i.e. lower ratios Q

b

=

Q

p

) show higher V

s

=

V

f

values.

●

In general, based on what was previously mentioned,

higher values of S

o

and R and lower values of d, SG, and

Q

b

=

Q

p

lead to higher sediment velocities V

s

.

3.2. Evolutionary polynomial regression model

A new regression-based model was developed here to predict

the dimensionless ratio V

s

=

V

f

during flushing operation. The

new model includes the group of parameters identified in

previous studies (Ab Ghani and Azamathulla

2011

; Ebtehaj

and Bonakdari

2016

; May et al.

1996

; Montes, Kapelan, and

Saldarriaga

2021

) and the graphic analysis carried out for the

experimentally collected data, as shown in

Figure 5

.

Evolutionary polynomial regression (EPR) is a hybrid regres-

sion technique that combines numerical and symbolic regression

(Giustolisi and Savic

2006

,

2004

). In its original formulation, it

used single-objective genetic algorithms to explore the formula

space, and then it estimates the least-squares regression coeffi-

cients. This technique has proved to be effective when the

number of polynomial terms is not large (Giustolisi and Savic

2009

). To solve these issues, Giustolisi and Savic (Giustolisi and

Savic

2009

) introduced the EPR technique combined with

a Multi-Objective Genetic Algorithm (MOGA). This novel techni-

que maximises the model accuracy (i.e. minimises the sum of

squared errors) and minimises the number of polynomial coeffi-

cients, and therefore improves the exploration of the space of

Table 1.

(Continued).

Run no.

S

o

D

Y

R

d

SG

y

s

t

b

t

p

Q

b

Q

p

V

f

V

s

(%)

(mm)

(mm)

(mm)

(mm)

(-)

(mm)

(s)

(s)

(l s

−1

)

(l s

−1

)

(m s

−1

)

(m s

−1

)

74

0.644

209

45.95

25.29

2.60

2.64

8.76

101

17

0.03

5.42

0.64

0.01

75

0.644

209

52.17

28.92

2.60

2.64

7.96

101

16

0.03

7.22

0.71

0.03

76

0.644

209

29.87

16.87

2.60

2.64

6.26

101

21

0.11

2.06

0.48

0.01

77

0.644

209

33.61

19.44

2.60

2.64

5.39

101

19

0.10

2.75

0.54

0.01

78

0.644

209

44.28

24.82

2.60

2.64

7.45

101

18

0.02

5.17

0.64

0.02

79

0.644

209

47.12

26.13

2.60

2.64

8.22

101

18

0.01

5.90

0.66

0.02

80

0.644

209

38.03

21.54

2.60

2.64

6.72

101

19

0.08

3.80

0.58

0.01

81

0.644

209

41.49

23.59

2.60

2.64

6.49

101

18

0.05

4.59

0.62

0.02

82

0.644

209

43.13

23.90

2.60

2.64

8.22

101

17

0.04

5.55

0.61

0.01

83

0.644

209

44.99

24.43

2.60

2.64

9.60

101

16

0.02

6.11

0.62

0.02

84

0.644

209

38.93

21.05

2.60

2.64

9.31

101

18

0.04

4.51

0.55

0.01

85

0.644

209

47.10

25.93

2.60

2.64

8.76

101

17

0.02

5.83

0.65

0.01

86

0.644

209

38.30

22.59

0.47

2.66

3.91

101

17

0.10

4.36

0.62

0.06

87

0.644

209

51.25

29.60

0.47

2.66

3.68

101

16

0.00

7.36

0.76

0.11

88

0.644

209

52.44

29.99

0.47

2.66

4.65

101

15

0.01

7.64

0.75

0.10

89

0.644

209

29.07

17.09

0.47

2.66

4.40

101

19

0.21

2.22

0.50

0.03

90

0.644

209

33.05

19.59

0.47

2.66

3.91

101

17

0.19

2.65

0.56

0.04

91

0.644

209

41.19

24.21

0.47

2.66

3.86

101

18

0.04

4.99

0.65

0.08

92

0.644

209

56.85

32.46

0.47

2.66

3.51

101

15

0.00

8.02

0.81

0.13

93

0.644

209

39.63

23.20

0.47

2.66

4.40

101

17

0.07

4.08

0.62

0.05

94

0.644

209

43.42

25.52

0.47

2.66

3.46

101

17

0.08

4.99

0.68

0.06

95

0.644

209

47.40

27.47

0.47

2.66

4.21

101

16

0.04

5.56

0.71

0.07

96

0.644

209

30.86

18.45

0.47

2.66

3.46

101

19

0.32

2.08

0.54

0.03

97

0.644

209

32.77

19.21

0.47

2.66

4.59

101

20

0.11

2.80

0.54

0.04

98

0.644

209

42.21

24.97

0.47

2.66

3.03

101

19

0.41

4.22

0.67

0.06

99

0.644

209

37.41

21.71

0.47

2.66

5.18

101

19

0.09

3.79

0.59

0.05

100

0.644

209

41.66

24.19

0.47

2.66

4.86

101

17

0.07

4.63

0.64

0.05

101

0.644

209

43.34

25.14

0.47

2.66

4.78

101

18

0.06

5.71

0.66

0.06

102

0.644

209

48.65

28.13

0.47

2.66

4.21

101

16

0.03

6.67

0.72

0.09

103

0.644

209

36.32

21.27

0.35

2.65

4.59

101

18

0.06

4.24

0.58

0.05

104

0.644

209

51.00

29.01

0.35

2.65

5.60

101

15

0.01

6.81

0.73

0.08

105

0.644

209

50.99

29.11

0.35

2.65

5.18

101

15

0.01

6.90

0.73

0.09

106

0.644

209

28.62

16.45

0.35

2.65

5.39

101

18

0.23

2.00

0.48

0.02

107

0.644

209

32.66

18.92

0.35

2.65

5.26

101

17

0.19

2.67

0.53

0.03

108

0.644

209

42.79

24.72

0.35

2.65

5.18

101

16

0.07

4.80

0.65

0.04

109

0.644

209

54.41

30.76

0.35

2.65

5.60

101

17

0.00

7.36

0.76

0.07

110

0.644

209

37.13

21.55

0.35

2.65

5.18

101

18

0.10

3.75

0.59

0.03

111

0.644

209

41.56

24.21

0.35

2.65

4.59

101

17

0.08

4.71

0.64

0.05

112

0.644

209

45.08

25.81

0.35

2.65

5.73

101

17

0.07

5.47

0.67

0.05

113

0.644

209

54.08

30.60

0.35

2.65

5.60

101

15

0.03

7.31

0.76

0.08

114

0.644

209

29.46

16.96

0.35

2.65

5.39

101

20

0.19

2.02

0.49

0.03

115

0.644

209

33.04

18.92

0.35

2.65

5.90

101

19

0.13

2.74

0.53

0.03

116

0.644

209

44.81

25.64

0.35

2.65

5.82

101

17

0.04

5.18

0.66

0.04

117

0.644

209

48.43

27.71

0.35

2.65

5.39

101

17

0.02

5.88

0.70

0.05

118

0.644

209

39.31

22.65

0.35

2.65

5.60

101

18

0.09

3.92

0.60

0.04

119

0.644

209

41.99

24.16

0.35

2.65

5.60

101

17

0.08

4.59

0.63

0.04

120

0.644

209

43.59

25.04

0.35

2.65

5.60

101

18

0.04

5.64

0.65

0.04

121

0.644

209

44.65

25.62

0.35

2.65

5.60

101

17

0.06

6.12

0.66

0.07

6

C. MONTES ET AL.

symbolic formulas. EPR-MOGA considers some pseudo-

polynomial expressions such as (Giustolisi and Savic

2009

):

^

Y ¼ a

0

þ

X

m

j¼1

a

j

X

1

ð

Þ

ES j;1

ð

Þ

� . . . �

X

k

ð

Þ

ES j;k

ð

Þ

�

f

X

1

ð

Þ

ES j;kþ1

ð

Þ

�

�

� . . .

�

f

X

k

ð

Þ

ES j;2k

ð

Þ

�

�

(5)

where ^

Y is the vector of model predictions; ES and j the

matrix of candidate exponents and the inner function,

respectively, both selected by the user; m the number of

terms; a

0

the bias term; a

j

the adjustable parameters esti-

mated by linear least squares and X

j

the candidate expla-

natory variables. The inner function f defined by the user

can be logarithmic, exponential, tangent hyperbolic, or

secant hyperbolic, and must be selected according to the

physics of the problem studied. The EPR technique returns

a range of models showing the influence of different

explanatory factors by progressively adding these as

input variables to monomial formulas, starting from the

most important ones. For each EPR identified model, the

following performance indices are calculated: the Bayesian

Information Criterion (BIC) and the Coefficient of

Determination (R

2

), as shown in Equations (6) and (7),

respectively.

BIC ¼

1 þ d

log n

ð Þ

n

�

�

X

n

i¼1

Y

�

Y

ð

Þ

2

!

(6)

R

2

¼

1

P

n

i¼1

Y

�

Y

ð

Þ

2

P

n

i¼1

Y

�

Y

�

�

2

(7)

where Y

�

and Y are the observed and calculated data,

respectively, n is the number of data, d the number of

parameters included in the model and Y

�

the mean of

observed data. The Coefficient of Determination measures

the fraction of variance that can be explained. Note that

this coefficient varies between 0 and 1, where 1 denotes

a perfect match between observed and calculated data. The

Bayesian Information Criterion measures the trade-off

between accuracy and parsimony of the model. This mea-

sure penalises formulas with large number of parameters.

The model with the lowest BIC value is selected as optimal.

The new model was constructed to predict the dimension-

less relation V

s

=

V

f

, i.e., the vector of model predictions ^

Y is

defined as V

s

=

V

f

. The matrix of candidate exponents was

defined with values ranging from −2.50 to 2.50, considering

steps of 0.1, i.e. ES ¼

2:50; 1:40; . . . ; 1:40; 2:50

½

�

. The matrix

of candidate explanatory variables is defined as follows:

X

j

¼

ψ;

d

;

Q

b

Q

p

;

y

s

R

;

t

b

t

p

;

β

�

�

(8)

Using previous considerations, and randomly splitting the

experimental data collected on the 209 mm and 595 mm

pipes, for both training (75% of the data) and testing (25% of

the data) stages, the results shown in

Table 2

were obtained

using the EPR-MOGA strategy.

Table 2

shows the Pareto front (i.e. range of models) generated

by the EPR, together with the corresponding BIC and R

2

values. For

example, the best one input variable model includes only the

Shields parameter as an explanatory variable for predicting the

V

s

=

V

f

(V

s

=

V

f

¼

0:17ψ

0:5

). This is the least complex, i.e., most

parsimonious model hence, unsurprisingly, it has a rather low

prediction accuracy (BIC = −48.21 and R

2

= 0.38). In contrast, the

Figure 4.

Example of flow hydrographs and sediment bed position for several experiments shown in

Table 1

.

URBAN WATER JOURNAL

7

6-variable model includes all candidate explanatory factors

V

s

=

V

f

¼

2:48ψ

1:4 Q

b

Q

p

� �

0:3

d

R

�

0:9 y

s

R

�

0:1 t

b

t

p

� �

0:2

β

�

�

, resulting in

low parsimony model but with improved prediction accuracy

(BIC = −92.22 and R

2

= 0.64). Based on this, the model that

shows the best trade-off between accuracy and parsimony is the

model with three input variables. This model is shown in

Equation (9).

Figure 5.

Plots showing the relationships between the dimensionless velocity (V

s

=

V

f

) and other dimensionless variables in both acrylic and PVC pipe. Clustered results

by particle diameter.

Table 2.

Pareto solution provided by the EPR-MOGA strategy.

Terms of monomial formula

Performance Index

Number of inputs

Coefficient (a

j

)

ψ

Q

b

Q

p

d

R

y

s

R

t

b

t

p

β

BIC

R

2

1

0.17

0.50

-

-

-

-

-

−48.21

0.38

2

0.14

0.60

−0.10

-

-

-

-

−66.19

0.48

3

8.13

1.40

−0.30

0.90

-

-

-

−104.55

0.63

4

11.47

1.50

−0.30

1.00

0.10

-

-

−100.56

0.64

5

121.48

2.10

−0.20

1.60

0.80

0.10

-

−96.49

0.64

6

2.48

1.40

−0.30

0.90

0.10

−0.20

1.00

−92.22

0.64

8

C. MONTES ET AL.

V

s

V

f

¼

8:13

d

R

� �

0:90

RS

o

SG

1

ð

Þ

d

�

�

1:40

Q

b

Q

p

�

�

0:30

(9)

Or rearranging the above formula to simplify the d=R term:

V

s

V

f

¼

8:13

d

R

� �

0:50

S

o

SG

1

ð

Þ

�

�

1:40

Q

b

Q

p

�

�

0:30

(10)

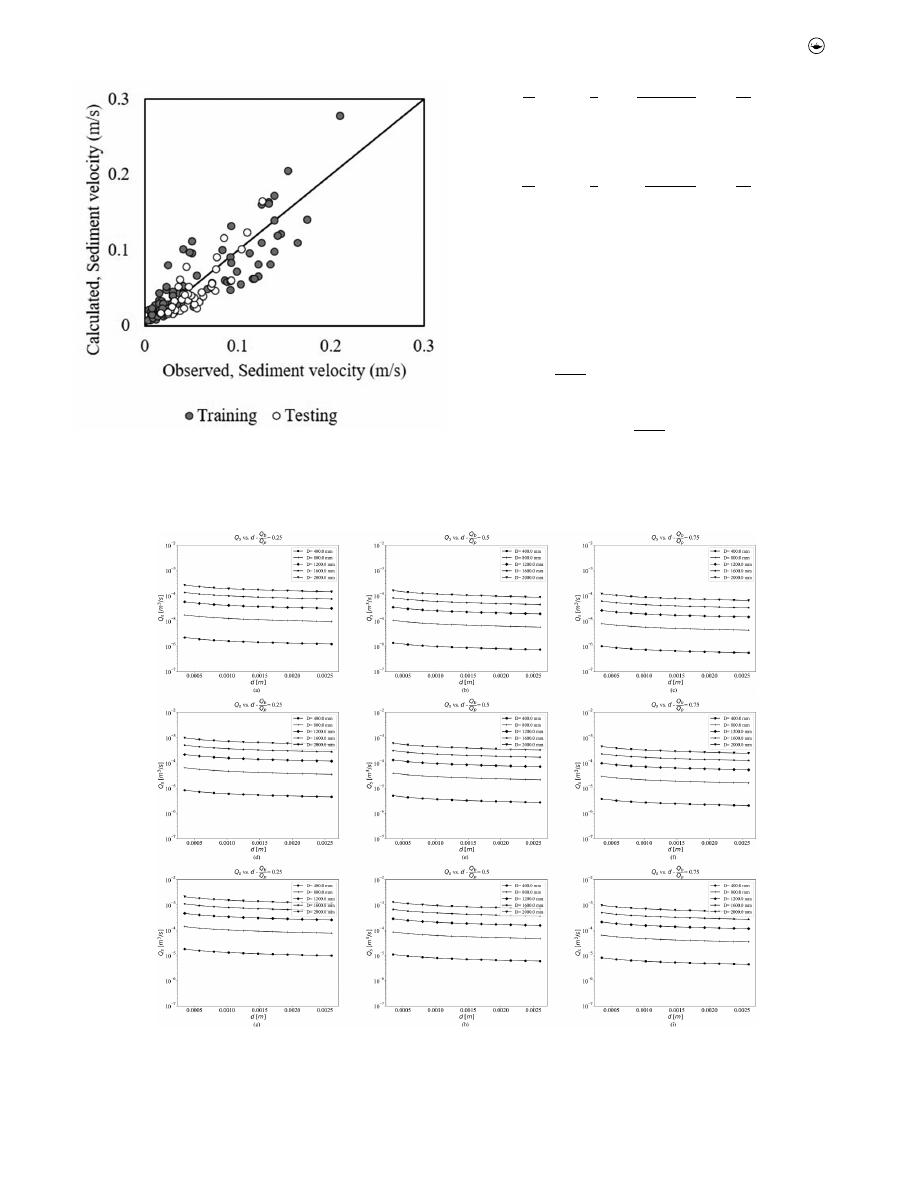

The obtained model was used to estimate the flushing effi-

ciency in larger pipes considering different flow conditions

and sediment characteristics. Further details are described in

the section below. The model’s accuracy can be seen in

Figure 6

for both training and testing datasets.

As it can be seen from the above equation and figure,

Equation (10) is consistent with the graphical analysis pre-

sented in

Figure 6

. Further, it can be seen from the model

obtained that

S

o

SG 1

ð

Þ

is the most important feature for predict-

ing the sediment velocity during the flushing cleaning opera-

tion – the more the pipe slope increases, the higher the particle

velocity is (note that the

S

o

SG 1

ð

Þ

parameter comes from the

Shields parameter). The Shields parameter shows the ratio

Figure 6.

EPR-MOGA model accuracy for both training and testing stage.

Figure 7.

Efficiency of flushing discharge vs particle diameter for several base and peak flow relations (0.25 < Q

b

=

Q

p

< 0.75) and pipe slope: a), b) and c) S

o

= 0.5%; d), e)

and f) S

o

= 1.0% and g), h) and i) S

o

= 1.5%.

URBAN WATER JOURNAL

9

between the hydrodynamic forces acting on the particles and

the resistance due to gravity. This parameter has been identi-

fied as one of the most relevant for predicting the incipient

motion in sewers (Delleur

2001

; Safari, Mohammadi, and Ab

Ghani

2018

; Wan Mohtar et al.

2018

). As mentioned above,

V

s

=

V

f

is inversely proportional to d=R, which is consistent with

the results shown by EPR-MOGA model.

4. Results and discussion

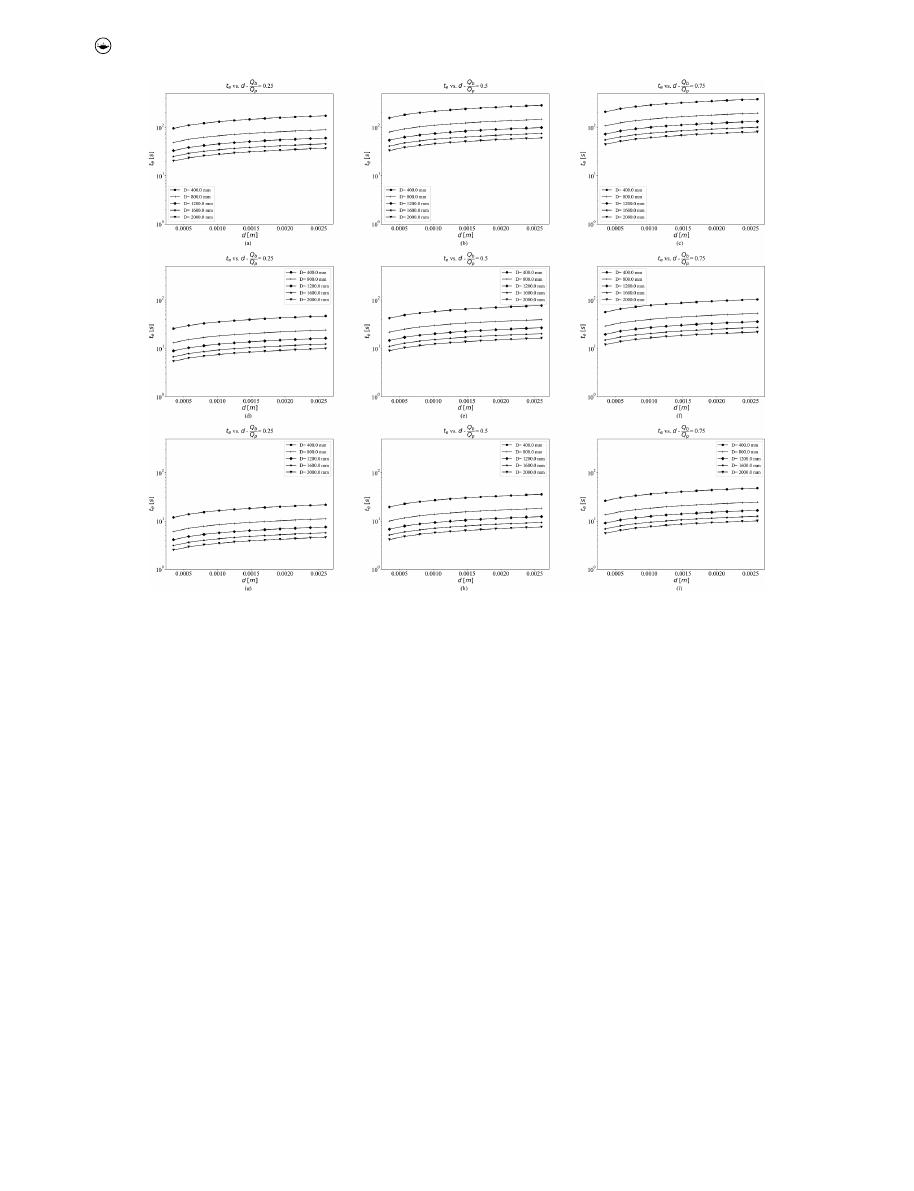

The new model shown in Equation (10) was used to generate

charts to estimate flushing efficiency as a function of the char-

acteristics of the discharged hydrograph, the pipe geometry

and the sediment properties. In this context, two flushing-

efficiency measures were defined as a function of the area of

deposited bed (A

s

) and the sediment velocity. The first measure,

Q

s

, is the volume of sediment removed by unit time (i.e. the

sediment flow rate = A

s

V

s

). The second measure, t

e

, is the

flushing time required to clean 1.0 m of the pipe (= 1=V

s

).

Figures 7 and 8

were constructed for several pipe diameters

using previous measures. To construct these figures, the less-

significant variables identified by the EPR-MOGA model (as

shown in

Table 2

) remained constant. The sediment thickness

was defined as y

s

=

D ¼ 1%, the specific gravity of the sediments

as 2.6, and the relation between the base and peak time of the

hydrograph as t

b

=

t

p

¼

5.0.

The following observations can be made from

Figures 7

and 8

:

●

Q

s

is inversely proportional to d and Q

b

=

Q

p

. In addition, Q

s

seems to be near-steady for particle diameters greater than

1.5 mm in pipes with diameters less than 800 mm. All above

for the same pipe slope and Q

b

=

Q

p

relation. Increasing the

pipe slope directly increase the sediment transport rate.

●

As the Q

b

=

Q

p

ratio increases, the sediment removal rate

decreases. For example, in

Figure 7(a

), when Q

b

=

Q

p

= 0.25

in a 1200 mm diameter pipe containing a deposited sedi-

ment bed with d = 1 mm, Q

s

= 0:5 � 10

−4

m

3

/s, while for

Q

b

=

Q

p

= 0.75 the Q

s

value changes to 0.2 � 10

−4

m

3

/s,

that is 60% less (as shown in

Figure 7(c

)).

●

Flushing discharges seem to be more efficient in larger

sewer pipes. The sediment transport rate can be five times

higher in 2000 mm diameter pipes, compared to

1200 mm diameter pipes.

●

Figure 8

shows a direct relationship between t

e

and d and

Q

b

=

Q

p

. Based on this, as d increases and Q

p

decreases, the

required flushing time to clean 1 meter of the pipe

increases. For example, in

Figure 8(d

) when Q

b

=

Q

p

=

0.25 in a 800 mm diameter pipe containing a deposited

sediment bed with d = 1.5 mm, t

e

= 20 sec, while for

Q

b

=

Q

p

= 0.75 the t

e

value changes to 45 sec, that is

125% more (as shown in

Figure 8(f

))

Figure 8.

Flushing time vs particle diameter for several base and peak flow relations (0.25 < Q

b

=

Q

p

< 0.75) and pipe slope: a), b) and c) S

o

= 0.5%; d), e) and f) S

o

= 1.0%

and g), h) and i) S

o

= 1.5%.

10

C. MONTES ET AL.

●

The flushing time decreases as the S

o

and D increase. That

is, flushing is a more efficient technique in large and steep

pipes.

4.1. Model comparison

To test the accuracy of the model shown in Equation (10), the

case study described in Laplace et al. (

2003

) was used. This case

study is located in Marseille, France, on a combined sewer net-

work. Specifically, this study considers an ovoid section of

1700 mm, 120 m long with a bottom slope of 0.03%. A near-

uniform deposited bed of 140 mm thickness was observed along

the entire length of the flume. The deposited bed was charac-

terised as coarser upstream (d = 8 mm) and finer downstream (d

= 0.6 mm). Full details are shown in Laplace et al. (

2003

).

Using a Hydrass-flushing gate located inside the section,

a series of flushes were conducted for testing the efficiency

on removing the deposited material. During each flush, a total

volume of 6.0 m

3

of water was discharged into the pipe. As

reported by Laplace et al. (

2003

), the mass of particles eroded

during the first flush was 6.3 kg, i.e., the removal rate was

1.08 kg of material per 1.0 m

3

of water (= 1.08 kg m

−3

).

Two existing procedures are compared with the new EPR-

MOGA model presented in Equation (10): the model proposed

by Bong, Lau, and Ab Ghani (

2013

) (i.e. Equation (3)) and the

design tables shown by Dettmar (

2007

). To compare the results,

several initial conditions are defined based on the case study

description, which are outlined as follows:

(1) Thickness of the deposited bed (y

s

) = 0.14 m

(2) Peak flow during flushing operation (Q

p

) = 100 l s

−1

(3) Specific gravity of the sediments (SG) = 2.60

(4) Mean particle diameter (d) = 0.6–8.0 mm

(5) Mass of material per meter of pipe = 54.22 kg m

−1

According to Bong, Lau, and Ab Ghani (

2013

), the number of

flushes required to move 1 m of deposited material can be

estimated by applying Equation (3). For this equation, the num-

ber of flushes is only a function of the thickness of the deposited

bed. As a result, 42 flushes (= 250.6 m

3

of water) can potentially

remove 54.22 kg of the deposited material (i.e. the removal rate is

0.21 kg m

−3

). Design tables proposed by Dettmar (

2007

) suggest

a flushing volume of 48 m

3

for a basic cleaning of the 150 m long

sewer (i.e. a full removing of the deposited material). No removal

rates are provided by Dettmar (

2007

).

Finally, using the new model proposed in this study, a range

of removal rates are obtained as a function of the mean particle

diameter. Potentially, a flushing volume of 10.18 m

3

can

remove 14.5 kg of deposited material with a mean particle

diameter of 0.6 mm (i.e. the removal rate is 0.40 kg m

−3

). By

changing the particle size of the deposited material to 8.3 mm,

the removal rate is 1.25 kg m

−3

.

As shown in

Table 3

, a direct comparison of the method

proposed by Dettmar (

2007

) and the results reported by

Laplace et al. (

2003

) is not possible. However, this method

seems to underestimate the real volume required to remove

the deposited bed. Relevant parameters such as the mean

particle diameter and the sewer hydraulics are not included in

this method. Due to the pipe slope in the case of study is almost

flat, obtaining minimum shear stress of 5.0 N m

−2

for cleaning

the pipe, according to Dettmar (

2007

), requires larger flows.

The model presented by Bong, Lau, and Ab Ghani (

2013

) is

a good approach for determining the number of flushes

required to move the deposited material. However, because

of the non-inclusion of relevant pipe hydraulics and sediment

parameters, the results are underestimated, compared to the

values reported by Laplace et al. (

2003

).

4.2. Model considerations

The new model presented here shows good prediction accu-

racy with the data reported by Laplace et al. (

2003

). This is

explained by the inclusion of relevant parameters for predicting

the removal rate during the flushing operation. The model also

shows good extrapolation capabilities under different sewer

diameters and a wide range of variations of the mean particle

diameter.

The Shields parameter was selected as the most important

one due to the highest value in the regression coefficient and

the Pareto solution provided by the EPR-MOGA strategy. This

was expected since this parameter determines the threshold

condition of sediment initiation motion. The sediment thick-

ness parameter is less important for defining the sediment

velocity during the flushing operation due to the low regres-

sion coefficient presented in

Table 2

. As a result, the model can

be used in both combined and storm sewers, where the sedi-

ment thickness ranges from 10 mm to 100 mm and 10 mm to

330 mm, respectively (Bong, Lau, and Ab Ghani

2016

).

The model includes the peak flow as an explanatory variable

for predicting sediment transport rate. Higher peak flow implies

a higher removal rate since higher shear stresses are generated

at the bottom of the pipe. The observed shear stress values

(ranging from 2.0 N/m

2

to 6.5 N/m

2

in the PVC pipe) are con-

sistent with those reported in the literature for the erosion and

transport of bed material (Dettmar

2007

; Campisano, Creaco,

Table 3.

Comparison of results for predicting the flushing efficiency in Laplace et al. (

2003

) case of study.

Reference

Removal

rate

[kg m

−3

]

Observations

Laplace et al. (

2003

)

0.93

Original case of Study reported in a trunk combined sewer in Marseille, France

Dettmar (

2007

)

-

Volume of water value reported to clean a pipe section of 150 m long. Relevant parameters as pipe slope and particle

diameter are not considered.

Bong, Lau, and Ab Ghani

(

2013

)

0.21

Good approximation. Experimental model (Equation (3)) obtained with a constant flume slope of 0.001.

EPR-MOGA Equation

(10)

0.4–1.25

Good performance for predicting the removal rate during flushing waves operation. Model consider relevant parameters as

the mean particle diameter and the pipe geometry.

URBAN WATER JOURNAL

11

and Modica

2008

; Yang et al.

2019

). However, since the model

only considers transport as bedload, some fine particles may be

eroded and transported in suspension (which has been identi-

fied as one of the major sources of pollution in CSO (Laplace

et al.

2003

; Saul et al.

2003

)), due to the high turbulence of the

flow. This is particularly important in well-graded materials

where wide ranges of mean particle sizes are present.

Even though the new model was developed considering

a wide range of variations in input variables, some limitations

exist. The granular material used in the experiments cannot

represent the cohesive properties of sediments found in real

sewer systems. As a result, an increased bed resistance to

erosion can be seen in practice (Campisano et al.

2019

). In

addition, the lowest pipe slope value considered during the

tests was 0.644%, which is higher than the minimum self-

cleansing value recommended in several industry design

codes and water utilities design manuals (e.g. Health Research

Inc (

2004

), as quoted by Montes et al. (

2019

)).

5. Conclusions

This study proposes a simple model to predict the sediment

transport rate in practice based on data collected from a set of

121 lab experiments conducted on a 209 mm diameter acrylic

pipe and 595 mm diameter PVC pipe. The data collected this

way were processed using the EPR-MOGA modelling techni-

que. A new model for predicting the sediment velocity during

flushing operation was developed and used for constructing

design charts. Based on the results obtained, the following

conclusions are made:

(1) The new model developed and presented here can pre-

dict the sediment transport rate during flushing dis-

charges accurately in practice. This model includes the

group of parameters that most affect the flushing effi-

ciency in sewer pipes.

(2) The sediment transport rate is principally affected by

four parameters: pipe slope, pipe diameter, particle dia-

meter and discharged peak flow. In pipes with large

diameters and slopes, the flushing is more effective.

This is because of the high regression exponents for

both

S

o

SG 1

ð

Þ

and d=R variables obtained in the EPR-

MOGA model presented here. The sediment transport

is not significantly affected by the value of the deposited

sediment thickness.

(3) The new model proposed outperforms the simplified

models and methods reported in the literature in terms

of removal sediment rate prediction. This is seen by the

better prediction accuracy shown when compared to

the case study reported by Laplace et al. (

2003

).

(4) Existing models such as Bong, Lau, and Ab Ghani (

2013

)

and Dettmar (

2007

) for predicting sediment transport

tend to underestimate the total volume of water

required to clean a deposited sediment bed. The EPR-

MOGA model is more accurate in predicting the sedi-

ment transport rate as this model includes parameters

affecting the flushing efficiency, such as flushing hydrau-

lics, pipe geometry and sediment properties.

Based on the conclusions mentioned above, the new flush-

ing model can be useful for designing flushing schemes during

the operational stage of existing sewer pipes in engineering

practice. Further research is recommended to test the model

proposed in real sewer pipes under different sediment (i.e.

cohesive materials) and hydraulic conditions.

Acknowledgement

The authors would like to thank Professor Orazio Giustolisi who developed

and made available for free the EPR-MOGA XL software used in this

research.

Disclosure statement

No potential conflict of interest was reported by the author(s).

ORCID

Carlos Montes

http://orcid.org/0000-0003-0758-4697

Sergio Vanegas

http://orcid.org/0000-0001-5786-9450

Zoran Kapelan

http://orcid.org/0000-0002-0934-4470

Luigi Berardi

http://orcid.org/0000-0002-6252-2467

Juan Saldarriaga

http://orcid.org/0000-0003-1265-2949

References

Ab Ghani, A., and H. Azamathulla.

2011

. “Gene-Expression Programming for

Sediment Transport in Sewer Pipe Systems.” Journal of Pipeline Systems

Engineering and Practice 2 (3): 102–106. doi:

10.1061/(ASCE)PS.1949-

1204.0000076

.

Ashley, R., J. Bertrand-Krajewski, T. Hvitved-Jacobsen, and M. Verbanck.

2004

. Solids in Sewers: Characteristics, Effects and Control of Sewer Solids

and Associated Pollutants. London: IWA Publishing. doi:

10.2166/

9781780402727

.

ASTM D854-14.

2014

. Standard Test Methods for Specific Gravity of Soil

Solids by Water Pycnometer. West Conshohocken, PA: ASTM

International.

Bajirao, T., P. Kumar, M. Kumar, A. Elbeltagi, and A. Kuriqi.

2021

. “Superiority

of Hybrid Soft Computing Models in Daily Suspended Sediment

Estimation in Highly Dynamic Rivers.” Sustainability 13 (2): 542.

doi:

10.3390/su13020542

.

Bertrand-Krajewski, J., J. Bardin, C. Gibello, and D. Laplace.

2003

. “Hydraulics

of a Sewer Flushing Gate.” Water Science and Technology 47 (4): 129–136.

doi:

10.2166/wst.2003.0237

.

Bong, C., T. Lau, and A. Ab Ghani.

2013

. “Hydraulics Characteristics of

Tipping Sediment Flushing Gate.” Water Science and Technology

68 (11): 2397–2406. doi:

10.2166/wst.2013.498

.

Bong, C., T. Lau, and A. Ab Ghani.

2016

. “Potential of Tipping Flush

Gate for Sedimentation Management in Open Stormwater Sewer.”

Urban

Water

Journal

13

(5):

486–498.

doi:

10.1080/

1573062X.2014.994002

.

Campisano, A., and C. Modica.

2003

. “Flow Velocities and Shear Stresses

during Flushing Operations in Sewer Collectors.” Water Science and

Technology 47 (4): 123–128. doi:

10.2166/wst.2003.0236

.

Campisano, A., C. Modica, E. Creaco, and G. Shahsavari.

2019

. “A Model for

Non-uniform Sediment Transport Induced by Flushing in Sewer

Channels.”

Water

Research

163:

114903.

doi:

10.1016/j.

watres.2019.114903

.

Campisano, A., E. Creaco, and C. Modica.

2004

. “Experimental and

Numerical Analysis of the Scouring Effects of Flushing Waves on

Sediment Deposits.” Journal of Hydrology 299 (3–4): 324–334.

doi:

10.1016/j.jhydrol.2004.08.009

.

Campisano, A., E. Creaco, and C. Modica.

2006

. “Experimental Analysis of the

Hydrass Flushing Gate and Laboratory Validation of Flush Propagation

12

C. MONTES ET AL.

Modelling.” Water Science and Technology 54 (6–7): 101–108.

doi:

10.2166/wst.2006.608

.

Campisano, A., E. Creaco, and C. Modica.

2007

. “Dimensionless Approach for

the Design of Flushing Gates in Sewer Channels.” Journal of Hydraulic

Engineering 133 (8): 964–972. doi:

10.1061/(ASCE)0733-9429(2007)

133:8(964)

.

Campisano, A., E. Creaco, and C. Modica.

2008

. “Laboratory Investigation on

the Effects of Flushes on Cohesive Sediment Beds.” Urban Water Journal

5 (1): 3–14. doi:

10.1080/15730620701726259

.

Caviedes-Voullième, D., M. Morales-Hernández, C. Juez, A. Lacasta, and

P. García-Navarro.

2017

. “Two-dimensional Numerical Simulation of

Bed-load Transport of a Finite-depth Sediment Layer: Applications to

Channel Flushing.” Journal of Hydraulic Engineering 143 (9): 04017034.

doi:

10.1061/(ASCE)HY.1943-7900.0001337

.

Chebbo, G., D. Laplace, A. Bachoc, Y. Sanchez, and B. Le Guennec.

1996

.

“Technical Solutions Envisaged in Managing Solids in Combined Sewer

Networks.” Water Science and Technology 33 (9): 237–244. doi:

10.1016/

0273-1223(96)00392-7

.

Creaco, E., and J. Bertrand-Krajewski.

2009

. “Numerical Simulation of

Flushing Effect on Sewer Sediments and Comparison of Four Sediment

Transport Formulas.” Journal of Hydraulic Research 47 (2): 195–202.

doi:

10.3826/jhr.2009.3363

.

De Sutter, R., M. Huygens, and R. Verhoeven.

1999

. “Unsteady Flow

Sediment Transport in a Sewer Model.” Water Science and Technology

39 (9): 121–128. doi:

10.1016/S0273-1223(99)00224-3

.

Delleur, J.

2001

. “New Results and Research Needs on Sediment Movement

in Urban Drainage.” Journal of Water Resources Planning and

Management 127 (3): 186–193. doi:

10.1061/(ASCE)0733-9496(2001)

127:3(186)

.

Dettmar, J.

2005

. “Beitrag zur Verbesserung der Reinigung von

Abwasserkanälen.” PhD diss., RWTH Aachen University.

Dettmar, J.

2007

. “A New Planning Procedure for Sewer Flushing.” Paper

presented at the NOVATECH 2007 – Sixth International Conference on

Sustainable Techniques and Strategies in Urban Water Management,

Lyon, June 25–28.

Dettmar, J., B. Rietsch, and U. Lorenz.

2002

. “Performance and

Operation of Flushing Devices - Results of a Field and Laboratory

Study.” Global Solutions for Urban Drainage: Proceedings of the Ninth

International Conference on Urban Drainage 1–10. doi:

10.1061/40644-

(2002)291

.

Ebtehaj, I., and H. Bonakdari.

2016

. “Bed Load Sediment Transport in Sewers

at Limit of Deposition.” Scientia Iranica 23 (3): 907–917. doi:

10.24200/

sci.2016.2169

.

Ebtehaj, I., H. Bonakdari, S. Shamshirband, Z. Ismail, and R. Hashim.

2017

.

“New Approach to Estimate Velocity at Limit of Deposition in Storm

Sewers Using Vector Machine Coupled with Firefly Algorithm.” Journal of

Pipeline Systems Engineering and Practice 8 (2): 04016018. doi:

10.1061/

(ASCE)PS.1949-1204.0000252

.

Fan, C.

2004

. Sewer Sediment and Control A Management Practices Reference

Guide, EPA/600/R-04/059. Washington, DC: U.S. Environmental Protection

Agency.

Fan, C., R. Field, W. Pisano, J. Barsanti, J. Joyce, and H. Sorenson.

2001

.

“Sewer and Tank Flushing for Sediment, Corrosion, and Pollution

Control.” Journal of Water Resources Planning and Management 127 (3):